Repairs and stitches the lifecycle closely together

What is It?

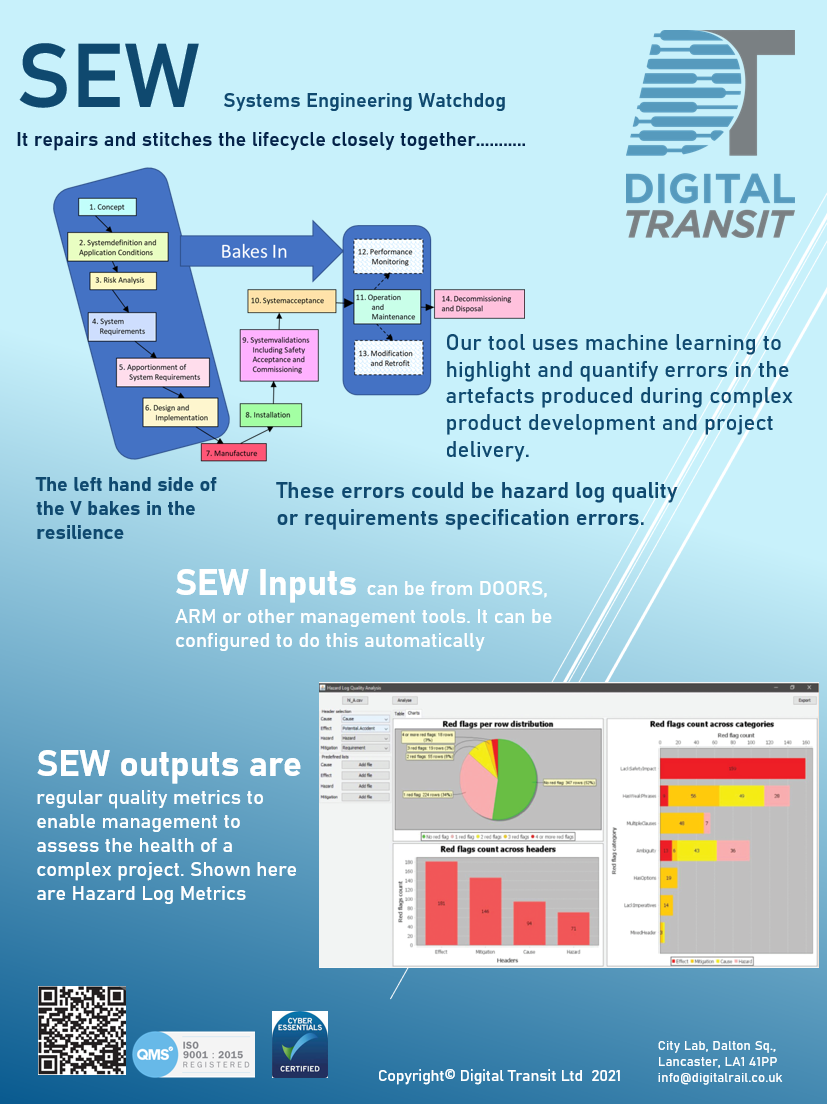

SEW is a tool that uses machine learning to highlight and quantify errors in the artefacts produced during complex product development and project delivery. SEW takes hazard logs and requirements documents as inputs, and can identify errors, low quality requirements, and other non-conformances within the documents. It outputs quality metrics so that the health of a complex project can be assessed.

A paper written by DTL on the tool can be read here: Click Here!

Beta Download

Click here to download and test the beta-version of SEW

Benefits

Having early knowledge that artefacts produced by the systems engineering and safety engineering are not of the requisite quality, compliance and timeliness is crucial for the delivery of a project. Engineers and managers working in rail sometimes place more importance on the technology than the documentation which is a mistake. In engineering, the documentation is as important as the kit.

By having constant information in the form of a dashboard, management can monitor the health of the project, especially in the left-hand side on the V-lifecycle.

The main reason for systems engineering is to provide timely information to management regarding the health of the project so that corrections can be made before the project goes off the side of the piste. There are many examples of this happening such as Cross Rail.