Digital Transit, in cooperation with the Engineering Department at Lancaster University, are developing the ‘Automatic Deployable Train Step Unit’, or Deployable Step for short. The step aims to minimise the gap at the interface between a train and the railway station platform.

Boarding and alighting the train carriage is one of the highest risk aspects of rail travel. Risk to passengers at the Platform Train Interface (PTI) is equivalent to approximately 13 equivalent fatalities each year, and accounts for 48% of the total passenger fatality risk on the mainline railway network in the United Kingdom (UK). The Rail Safety and Standards Board (RSSB) state that “The railway is a key way for people to access employment, health services, education and leisure. It should be accessible to all. This includes: Physical accessibility for the less able, elderly and those with children and luggage” [2, p.9]. Therefore, the rail industry has a legal and social responsibility to ensure that all passengers have safe access to this mode of public transport, and an engineering solution is required to overcome these problems at the PTI.

The problem is due in part to the physical distance between the train and platform, both vertically and horizontally. As well as creating a risk of passengers falling between the platform and the train, the gap means that people experience difficulties in accessing carriages. This particularly affects passengers with reduced mobility.

Platform height and width vary greatly on the railway and it would not be practicable to redesign all platforms to a standard height. The problem is exacerbated by the fact the train step position varies widely across train fleets.

So what is the solution?

The solution is a deployable step that automatically minimises the gap at any unique station platform and the corresponding gap present at the PTI.

Based upon the gap, a moveable step is deployable to a calculated position in the horizontal and vertical plane, coordinated in order to reduce the PTI gap to an acceptable distance. The step system determines the distance between the static step edge and the platform edge in the horizontal and vertical plane, and how far to extend the step so that the new gap is acceptable to passengers with additional needs.

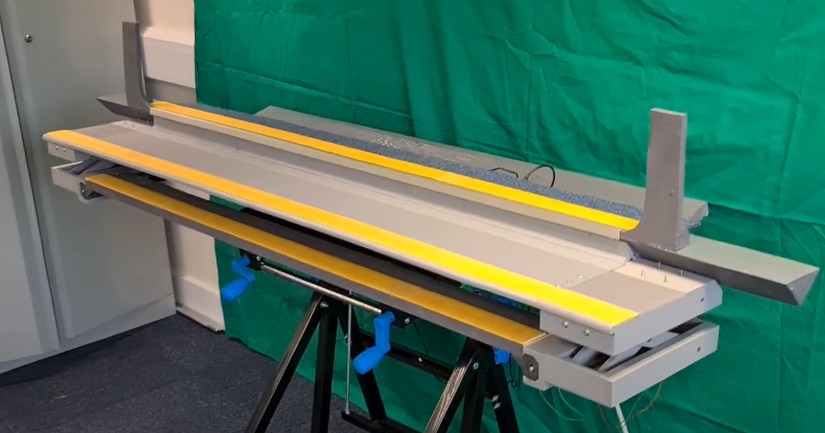

The deployable step consists of three parts: two mechanisms that attach to either side of a static step, and a secondary step that attaches to the bottom of the two aforementioned mechanisms. The step system can be made of any durable material. Inside the casing of the step mechanism two driving mechanisms are held, one allowing movement in the horizontal direction and another allowing movement in the vertical direction.

The deployable step is designed for railway applications and is fitted to rolling stock. It fits within the standard vehicle gauge of the train in accordance with the standard [RSSB GERT8073]. Finally, the deployable step is retrofittable or can be fitted to new trains and does not require intrusion inside the train body.